Back

Streamlining Quality Management Processes: The Role of APQP and PPAP Manager Software

Introduction:

In the ever-evolving landscape of manufacturing, ensuring product quality is paramount. Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) are integral components of the automotive industry, and their principles have found application in various manufacturing sectors. Managing these processes efficiently is crucial for organizations aiming to deliver high-quality products while meeting industry standards. In this blog post, we explore the benefits of utilizing APQP and PPAP Manager Software in streamlining these quality management processes.

I. Understanding APQP and PPAP:

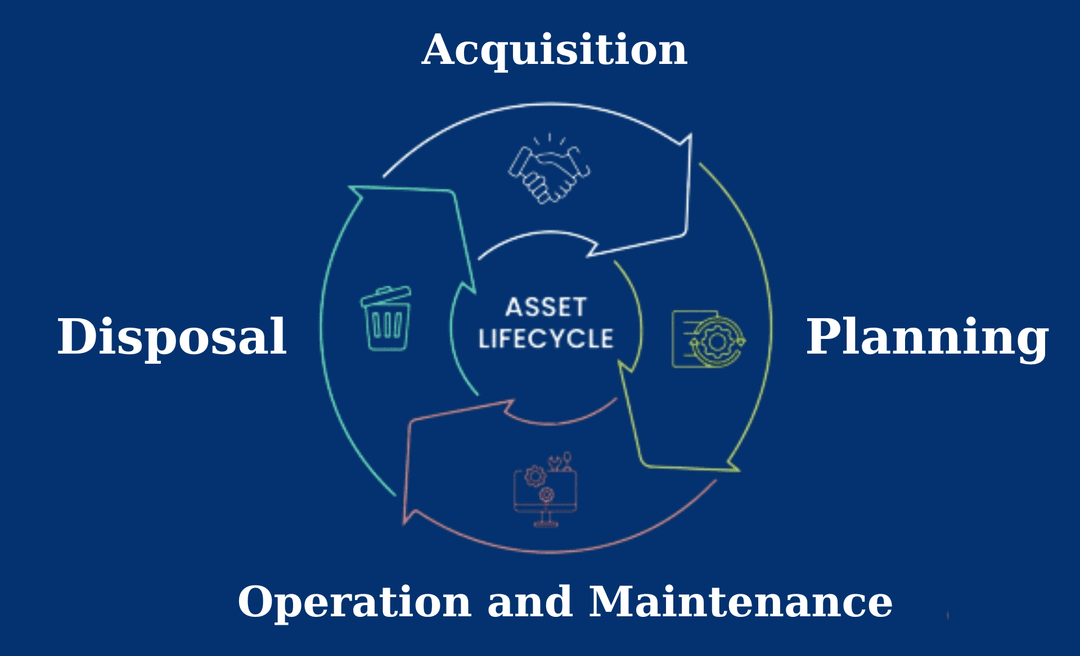

APQP is a structured process aimed at ensuring customer satisfaction by integrating quality into the product development cycle. It involves comprehensive planning and risk management to identify potential issues early in the production process.

PPAP, on the other hand, is the final step in the APQP process. It involves the submission of evidence to the customer that all production processes have been verified and are capable of consistently producing products meeting the specified requirements.

II. Challenges in Traditional APQP and PPAP Processes:

While APQP and PPAP are indispensable, the traditional manual methods of managing these processes can pose several challenges. These challenges include:

Data Management: Handling vast amounts of data associated with APQP and PPAP documentation can be overwhelming and prone to errors when managed manually.

Collaboration: Coordinating efforts across different teams and departments involved in APQP and PPAP can be challenging, leading to communication gaps and delays.

Version Control: Keeping track of document versions and changes becomes cumbersome, increasing the risk of using outdated information.

Audit Trail: Ensuring transparency and accountability through a clear audit trail is difficult with manual systems.

III. The Role of APQP and PPAP Manager Software:

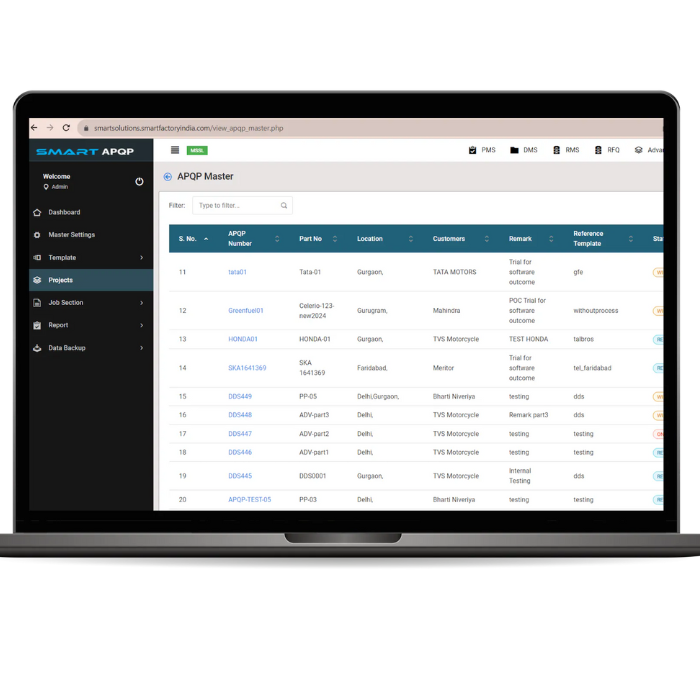

APQP and PPAP Manager Software address these challenges by providing a centralized and automated solution. Key features and benefits include:

Document Management:

Centralized repository for all APQP and PPAP documents.

Version control to track changes and updates.

Collaboration Tools:

Facilitates real-time collaboration among teams and departments.

Notifications and alerts to keep all stakeholders informed.

Automation:

Streamlines workflow processes, reducing manual effort.

Automated reminders for upcoming deadlines and tasks.

Risk Management:

Identifies and assesses risks early in the product development process.

Enables proactive risk mitigation strategies.

Data Analytics:

Provides insights through data analytics for continuous improvement.

Performance metrics to monitor the effectiveness of APQP and PPAP processes.

Audit Trail and Compliance:

Maintains a clear audit trail for accountability and compliance purposes.

Helps organizations adhere to industry standards and customer requirements.

What is APQP Software ?

APQP software refers to Advanced Product Quality Planning software. APQP is a framework used in the automotive industry and other manufacturing sectors to ensure that new products or processes meet specified quality standards. APQP involves various stages, including planning, design and development, product and process validation, and production.

APQP software is designed to facilitate and automate these stages, helping organizations manage and track the quality planning process more effectively. It typically includes features for collaboration, document management, risk assessment, and progress tracking, enabling teams to work together seamlessly to achieve high-quality outcomes in product development and manufacturing processes. The goal is to enhance efficiency, reduce errors, and ensure that products meet or exceed customer expectations.

What is PPAP Software?

xx

PPAP software refers to tools or applications designed to facilitate the management and execution of the Production Part Approval Process (PPAP). The PPAP is a standardized process in the automotive and other manufacturing industries, where suppliers demonstrate their ability to manufacture parts that meet the specified requirements.

PPAP software typically assists in organizing and automating the documentation and submission process required for PPAP. This may include features for managing various PPAP elements such as design records, control plans, process flow diagrams, and other documentation essential for product and process validation.

By using PPAP software, organizations can enhance efficiency, accuracy, and compliance in the PPAP process, ensuring that suppliers can consistently meet the quality standards set by their customers. This type of software is valuable in industries where stringent quality control and adherence to specific standards are crucial.

IV. Conclusion:

In conclusion, the implementation of APQP and PPAP Manager Software is a strategic move for organizations committed to delivering high-quality products efficiently. By overcoming the challenges associated with manual processes, these software solutions enhance collaboration, transparency, and overall effectiveness in managing APQP and PPAP. Embracing technology in quality management not only ensures compliance with industry standards but also positions companies to thrive in an increasingly competitive market by consistently delivering products that meet or exceed customer expectations.