Back

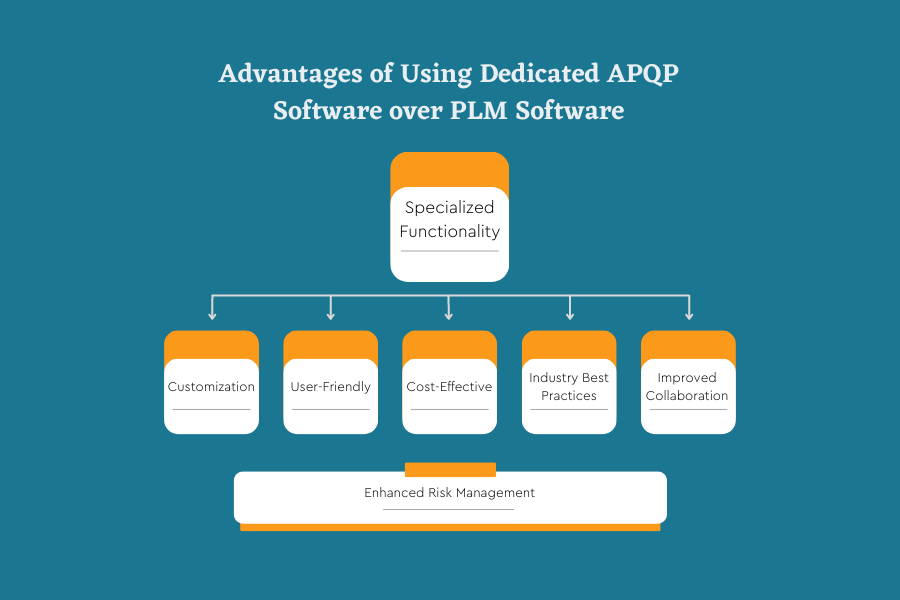

Advantages of Using Dedicated APQP Software over PLM Software

As business enterprises become more sophisticated, the demand for dedicated software tools to manage specific tasks and workflows has increased significantly. One such crucial workflow in many industries, particularly automotive, is Advanced Product Quality Planning (APQP). Traditionally, Product Lifecycle Management (PLM) software has been leveraged for this purpose, but there's a growing consensus favoring the use of dedicated APQP software. Here are some key advantages of this shift.

- Tailored Functionality

APQP software is designed specifically for managing quality control processes in the product development lifecycle. It comes equipped with the necessary tools to handle all stages of APQP – from design and development, process planning, and product validation, to continuous improvement. While PLM software does provide a broad overview of the product lifecycle, it lacks the tailored functionality of dedicated APQP software, which can lead to more streamlined and efficient processes. - Enhanced Compliance Management

Regulatory compliance is a crucial part of quality control, and dedicated APQP software is often equipped with compliance management tools. These can help businesses stay updated with industry standards and regulations, something that is increasingly important in heavily regulated sectors. PLM software typically doesn't have this level of in-depth compliance functionality, which can make maintaining standards more labor-intensive. - Focused Reporting and Analysis

APQP software often includes built-in reporting and analysis tools designed specifically for quality control processes. These can provide detailed insights into potential product defects, process inefficiencies, and areas for improvement. In comparison, while PLM software can offer a wealth of data, its broad focus means that it may not provide the detailed quality control insights that APQP software can offer. - Better Risk Management

Risk management is an integral part of the APQP process. APQP software often includes dedicated risk assessment tools to identify potential risks earlier in the product development cycle. This feature helps teams mitigate these risks before they become significant issues. PLM software, with its more generalized view, may not offer the same level of focused risk assessment. - Improved Collaboration

With a centralized platform, APQP software improves collaboration among teams. Everyone involved in the product quality planning process can access the same data, updates, and changes, promoting cross-functional synergy. While PLM software also promotes collaboration, the specialized focus of APQP software on quality planning makes it easier for relevant teams to work together effectively.

- Tailored Functionality

APQP software is designed specifically for managing quality control processes in the product development lifecycle. It comes equipped with the necessary tools to handle all stages of APQP – from design and development, process planning, and product validation, to continuous improvement. While PLM software does provide a broad overview of the product lifecycle, it lacks the tailored functionality of dedicated APQP software, which can lead to more streamlined and efficient processes. - Enhanced Compliance Management

Regulatory compliance is a crucial part of quality control, and dedicated APQP software is often equipped with compliance management tools. These can help businesses stay updated with industry standards and regulations, something that is increasingly important in heavily regulated sectors. PLM software typically doesn't have this level of in-depth compliance functionality, which can make maintaining standards more labor-intensive. - Focused Reporting and Analysis

APQP software often includes built-in reporting and analysis tools designed specifically for quality control processes. These can provide detailed insights into potential product defects, process inefficiencies, and areas for improvement. In comparison, while PLM software can offer a wealth of data, its broad focus means that it may not provide the detailed quality control insights that APQP software can offer. - Better Risk Management

Risk management is an integral part of the APQP process. APQP software often includes dedicated risk assessment tools to identify potential risks earlier in the product development cycle. This feature helps teams mitigate these risks before they become significant issues. PLM software, with its more generalized view, may not offer the same level of focused risk assessment. - Improved Collaboration

With a centralized platform, APQP software improves collaboration among teams. Everyone involved in the product quality planning process can access the same data, updates, and changes, promoting cross-functional synergy. While PLM software also promotes collaboration, the specialized focus of APQP software on quality planning makes it easier for relevant teams to work together effectively.

Check this out too : Link

Internal Link: link

In conclusion, while PLM software has been a mainstay in managing the product lifecycle, the shift towards dedicated APQP software brings significant advantages. By focusing on tailored functionality, enhanced compliance management, detailed reporting, better risk management, and improved collaboration, APQP software can deliver superior quality control and efficiency in product development processes. As businesses continue to seek ways to optimize their operations, the move towards more specialized software tools like APQP software seems not only strategic but also inevitable.