Back

Revolutionizing Automotive Quality: The Power of APQP Software

Introduction:

In the fast-paced world of automotive manufacturing, staying ahead of the competition requires precision, efficiency, and uncompromising quality. Advanced Product Quality Planning (APQP) has long been a cornerstone of success in the industry. However, as technology evolves, so do the tools at our disposal. Enter APQP software—a game-changer that is reshaping how manufacturers approach quality management. In this blog post, we will explore the ins and outs of APQP software, its benefits, and why it's becoming an indispensable asset in the automotive sector.

What Is APQP Software -

APQP software streamlines Advanced Product Quality Planning processes in the automotive industry. It aids in project planning, risk management, document control, collaboration, supplier interaction, audit trails, and compliance management. The software ensures efficient quality planning and reduces the risk of defects and recalls. It applies beyond the automotive sector to various manufacturing industries.

Understanding APQP Software:

APQP software is a digital solution designed to streamline and enhance the Advanced Product Quality Planning process. It acts as a centralized hub, bringing together various stages of product development, from initial design to final production. This software facilitates collaboration, improves communication, and ensures that all stakeholders are on the same page, ultimately contributing to the delivery of high-quality products.

Key Features and Benefits:

- Collaborative Design Process: APQP software promotes collaboration among cross-functional teams involved in product development. Designers, engineers, and quality assurance professionals can seamlessly work together, sharing real-time updates and feedback. This ensures that potential issues are identified early in the design phase, preventing costly errors later on.

- Risk Management and Mitigation: One of the standout features of APQP software is its robust risk management capabilities. The software helps identify potential risks at every stage of the production process and provides tools for effective mitigation. This proactive approach minimizes the likelihood of defects and non-conformities, safeguarding product quality.

- Real-time Data Insights: Access to real-time data is crucial for making informed decisions. APQP software provides comprehensive dashboards and analytics tools that offer insights into various aspects of the production process. From supplier performance to design changes, manufacturers can leverage data-driven insights to continuously improve their operations.

- Regulatory Compliance: In the highly regulated automotive industry, compliance with industry standards and regulations is non-negotiable. APQP software ensures that all processes align with industry-specific standards, such as ISO/TS 16949. This not only helps in meeting regulatory requirements but also enhances the overall credibility of the manufacturing process.

- Enhanced Communication: Clear and effective communication is the cornerstone of successful product development. APQP software facilitates communication by providing a centralized platform for documentation, collaboration, and information sharing. This reduces the risk of misunderstandings and ensures that all stakeholders are well-informed.

Disadvantages of production processes without APQP software

The absence of Advanced Product Quality Planning (APQP) software in production processes can result in several disadvantages, including:

- Inefficient Planning: Without APQP software, planning for product development may lack structure and efficiency, leading to delays, oversights, and potential quality issues.

- Increased Risk: The absence of systematic risk management tools may result in a higher likelihood of unidentified risks and a lack of proactive measures to mitigate potential issues during production.

- Poor Documentation Control: Manual document management can lead to disorganization, version control problems, and difficulty in tracking and maintaining the various documents associated with quality planning.

- Limited Collaboration: The lack of a centralized platform for collaboration can hinder communication and coordination among different teams involved in the production process, potentially leading to misunderstandings and errors.

- Supplier Relationship Challenges: Without dedicated features for supplier collaboration, maintaining effective communication and ensuring that suppliers meet quality standards may become challenging.

- Audit Trail Issues: The absence of automated audit trails may result in difficulties in tracking changes and activities within the production process, affecting accountability and traceability.

- Compliance Risks: Without software support, ensuring compliance with industry standards and regulations becomes more challenging, increasing the risk of non-compliance.

- Quality Control Challenges: Manual processes may hinder the implementation of robust quality control measures, leading to an increased likelihood of defects and a potential negative impact on product reliability.

In summary, the disadvantages of production processes without APQP software include inefficiencies in planning, heightened risk exposure, issues with document control, limited collaboration, challenges in supplier relationships, audit trail problems, compliance risks, and difficulties in implementing effective quality control measures. The adoption of APQP software helps address these issues, contributing to more streamlined and quality-driven production processes.

Advantages of production with APQP software

Utilizing Advanced Product Quality Planning (APQP) software in production processes offers several advantages, including:

- Efficient Planning: APQP software facilitates structured and efficient planning for product development, helping teams organize tasks and timelines effectively.

- Risk Management: The software provides tools for systematic risk identification and management, allowing teams to proactively address potential issues during production.

- Document Control: APQP software ensures organized and centralized document management, improving version control, accessibility, and traceability of important documents related to quality planning.

- Collaboration Enhancement: With features for collaboration, the software promotes effective communication and coordination among different teams involved in the production process, reducing the likelihood of misunderstandings.

- Supplier Collaboration: APQP software includes tools for managing communication and collaboration with suppliers, ensuring that they meet quality standards and contribute to a seamless production process.

- Audit Trail: Automated audit trails in the software provide a transparent record of changes and activities within the production process, enhancing accountability and traceability.

- Compliance Assurance: The software helps in ensuring compliance with industry standards and regulations through built-in tools and features, reducing the risk of non-compliance.

- Quality Control Optimization: APQP software supports the implementation of robust quality control measures, contributing to the prevention of defects and the enhancement of overall product reliability.

- Data Analysis: Many APQP software solutions offer analytics capabilities, allowing teams to analyze data related to the production process, identify trends, and make informed decisions for continuous improvement.

- Time and Cost Savings: By streamlining processes and improving efficiency, APQP software can lead to time and cost savings in product development and production.

In summary, the advantages of production with APQP software include efficient planning, enhanced risk management, improved document control, collaboration facilitation, supplier collaboration, automated audit trails, compliance assurance, quality control optimization, data analysis capabilities, and potential time and cost savings. These benefits contribute to the overall success and quality of the production process.

Functions of our APQP software

Our APQP software provides essential functions for streamlined production:

- Project Planning: Structured planning for development tasks.

- Risk Management: Tools for identifying and managing risks.

- Document Management: Centralized storage with version control.

- Collaboration: Facilitates communication among teams.

- Supplier Collaboration: Ensures supplier adherence to standards.

- Audit Trail: Automated record of changes for accountability.

- Compliance Management: Monitors and enforces industry standards.

- Quality Control: Supports inspection plans and defect prevention.

- Data Analysis: Enables analysis of production-related data.

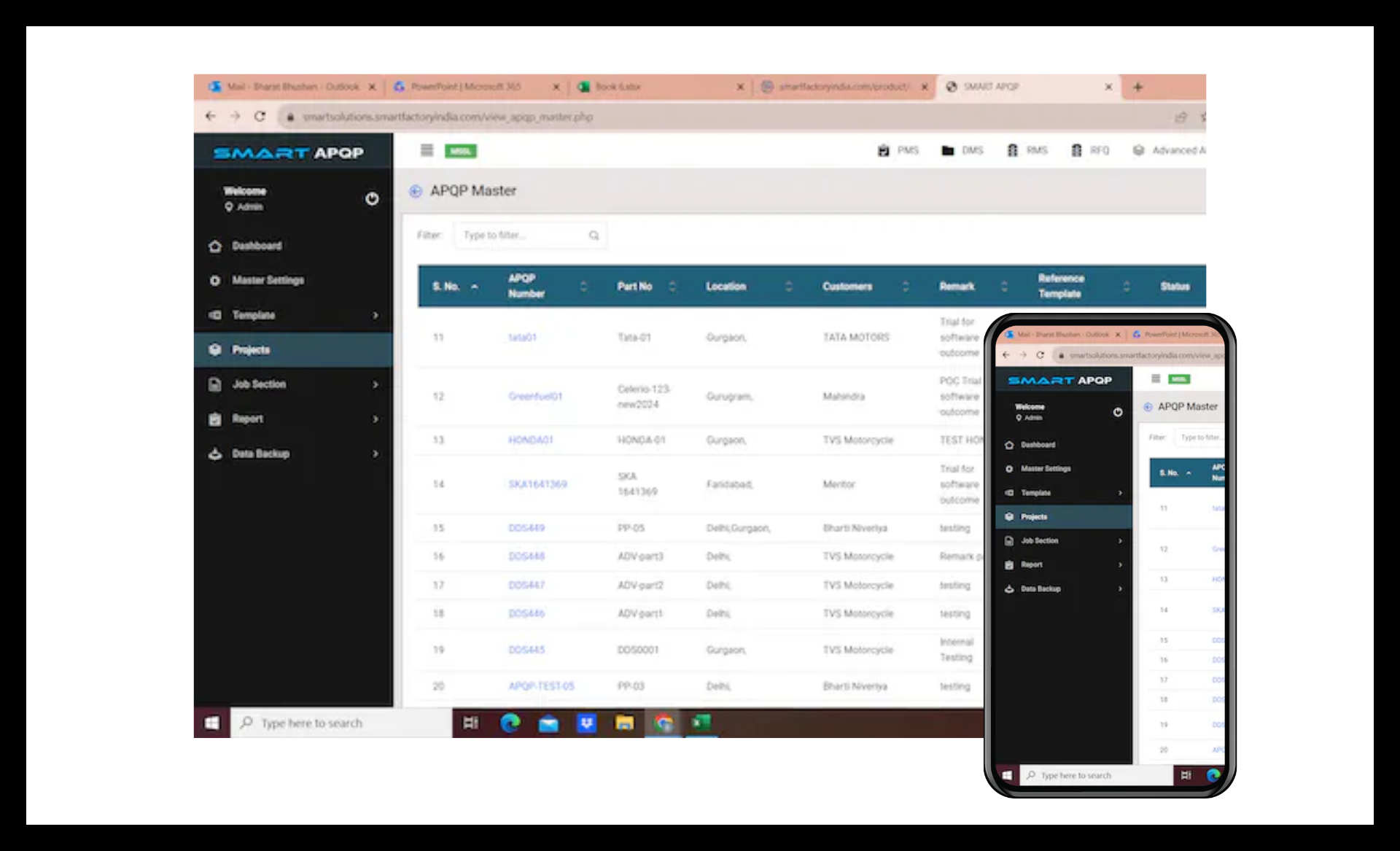

- Dashboard: Visual overview of key metrics and production status.

- Task Management: Tracks tasks, deadlines, and milestones.

- Change Management: Manages changes with proper documentation.

- Decision-Making: Supports collaborative decision-making.

- Training and Support: Provides resources for effective utilization.

Conclusion:

As the automotive industry continues to evolve, embracing technological advancements becomes imperative for sustained success. APQP software is more than just a tool; it's a catalyst for innovation, collaboration, and continuous improvement. Manufacturers who leverage the power of APQP software are not only meeting industry standards but are setting new benchmarks for quality and efficiency. In a world where precision and excellence are paramount, APQP software is the key to unlocking the full potential of automotive manufacturing.